Auto Anneal Gen 2 For Sale

Suitable concepts for every requirement

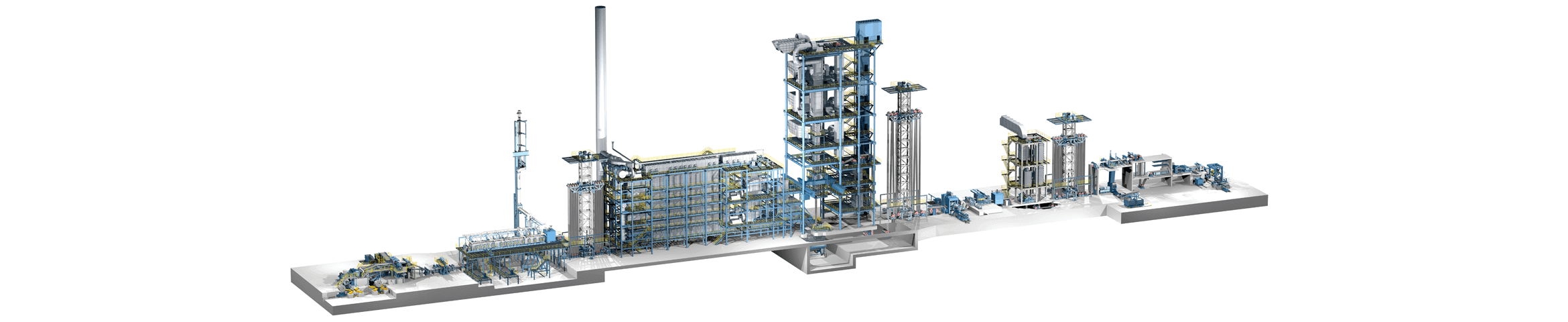

It has been proven that SMS has the competence to design, engineer, erect and put into operation modern cold strip processing lines. Supported by the various specialized companies within the SMS group, which offer equipment and services for annealing lines and galvanizing lines the lines are delivered from a single system supplier.

Hot-Dip Galvanizing line

Continuous Annealing line

Continuous Annealing line

with gas and water cooling

Universal Annealing and

galvanizing line

All purpose line (Annealing, galvanizing, gas cooling, water cooling)

Horizontal Galvanizing line (Prduction of galvanized strip mainly for the construction industry)

Heat-to-Coat galvanizing line (Pickling and galvanizing of Hot-strip

for several applications)

Multi-phase steels, which are high strength and very ductile, are increasingly being used for car components. These high-strength yet easily deformable steels must meet the highest quality requirements for use in automobiles.

Annealing and galvanizing lines from the SMS group are characterized in particular by the excellent quality of the end product, high efficiency and economy, as well as enormous capacities. In recent years various improvements and new technical solutions have been developed, particularly regarding line concepts, furnace technology, galvanizing technology and post-treatment.

In the lines, account is taken of the stringent demands on surface quality. This commences with cleaning, which is followed by surface-friendly annealing, and high-grade coating technologies for the application of a zinc layer, passivation or preserving oils. Advanced annealing and cooling strategies are implemented, together with a skin-pass millstand for targeted post-treatment, in order to achieve outstanding material strengths.

System supply

Roll coater for passivation

Electrostatic oiling machine

Quality monitoring systems

Electrical and Automation Systems

Operation and Visualization

Our ergonomically designed control stations support the activities of your operating personnel. Included here is our new HMI system which guides them intelligently through the process.

Electrical and Automation Systems

Plug & Work

Many customers around the world have already benefited from Plug & Work for more than 100 new plant and modernization projects.

Electrical and Automation Systems

Service

Always at your side. Quick and reliable, worldwide service and training for electrical and automation systems.

As a key to increasing the efficiency of modern processing lines More information Level 2 system

Technological controls for inline skin pass mill More information Technological skin pass mill controls

Innovative system with diagnostics for startup, devices, sequences, safety, and plant More information X-Pact® Basic Automation

Coating control for chem-coater, prime-coater and finish-coater More information X-Pact® Coating Control

Switch mode power rectifier for electrolytic processing lines More information X-Pact® High Current

Innovative line drive control combined with optimal drive hardware More information X-Pact® Line Drive Control

Production rate optimization More information X-Pact® Looper Control

Control of flatness with tension leveler More information X-Pact® Tension Leveler Model

Stand-alone measuring system for flatness control perfectly tailored to your process requirements. More information X-Shape Flatness Measurement and Control

Digital counterpart of a customer-specific plant More information Digital twin

3D real-time simulation of technology prior to installation More information Plug & Work

Solution for smooth process flow and constant high quality More information Product quality analyzer (PQA®)

Always at your side, quickly and dependably, worldwide More information Remote service

Safeguarding plant lifetime More information Virtualization

Systematic analysis of data in an electronic form More information X-Pact® Business Intelligence

Low voltage frequency converter as integral part of X-Pact® More information X-Pact® Drive

Energy management for metallurgical plants and rolling mills More information X-Pact® Energy Advisor

Production planning and scheduling for all production units in the plant More information X-Pact® MES 4.0

The "transparent" plant More information X-Pact® Process Condition Analyzer (PCA)

New standard for the future automatic control of complex plants More information X-Pact® Process Guidance

Intelligent sensor system and camera-based solutions More information X-Pact® Sense

Easy access on process results - Full information and control everywhere More information X-Pact® Vision Mobile Operation

Innovative HMI and new control station More information X-Pact® Vision Operation and Visualization

Service

Consulting & Training

However, not only a service partner for your plants and machines, SMS group is also there for your staff. Furthermore, You can enroll on standardized and individual training programs designed for you by our SMS TECademy. That ensures you strengthen your competence as a plant owner.

Service

Maintenance & Repairs

Whether you require one-off equipment checks, continuous condition monitoring, remote service, or regular plant inspections: our service experts will take care of it all. You can even outsource your complete maintenance operations to us. This ensures excellent plant availability plus best production results.

Service

Spare parts & Logistics

When the spare parts you need are no longer available or the new generation is not 100% compatible, you risk plant standstills. That's why SMS group constantly monitors the availability of all parts and, where necessary, offers modern alternatives - even for parts from third-party suppliers. This ensures competitiveness and full productivity over the entire life cycle of your plant.

Service

Upgrades & Modernization

Even plants "built to last" need to be critically examined from time to time, because markets and production processes are continuously evolving. Together with you, our service experts will find the best revamp options for your requirements. Once again bang up to date, your plants will then be ready to bolster your strong position on the market.

Strong surfaces to endure thermal and mechanical stress. Pick-up reduction by up to 93% increases campaign life. More information Coated furnace rolls

Digital documentation: First step to a smart plant. More information eDoc

For easy identification of defects and malfunctions and quick initiation of measures for fault elimination. More information Emergency support - Remote Service

Regular inspections and maintenance form the basis for safeguarding the efficiency of your equipment. More information Equipment check

SMS group offers you the full range of services along the value chain, while you can focus entirely on your core competences. More information Long-term maintenance services

Protect your most valuable asset - your employees - with the SMS group Safety Locator! More information Safety Locator

Digitalize your maintenance with SMS group! More information Smart Maintenance

The SMS group repairs and restores zinc pot equipment. Results: Reliable performance and superior final product quality. More information Zinc pot maintenance

Auto Anneal Gen 2 For Sale

Posted by: langstonfareve.blogspot.com

Source: https://www.sms-group.com/plants/all-plants/annealing-and-galvanizing-lines

0 Response to "Auto Anneal Gen 2 For Sale"

Post a Comment